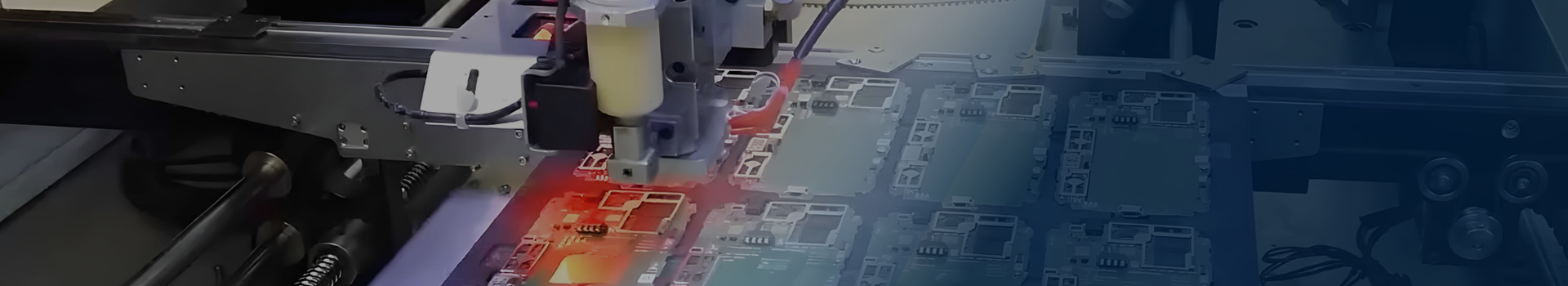

Screwing household appliances usually requires the use of specialized electric screwdrivers or automatic screwdrivers. In the manufacturing and maintenance process of household appliances, screwing is a common step. To ensure the tightness and efficiency of screws, electric screwdrivers or automatic screwdrivers are usually chosen. These tools can quickly tighten or loosen screws, greatly improving work efficiency. ?

Definition and core tools for screwing household appliances

Screwing household appliances is a process of assembling screws using an electric screwdriver or automatic screw machine, with the core goal of improving screw tightening efficiency and consistency. The main tools include:

?

Electric screwdriver: adaptable to different screw specifications, providing adjustable torque to avoid slipping or over tightening issues; ?

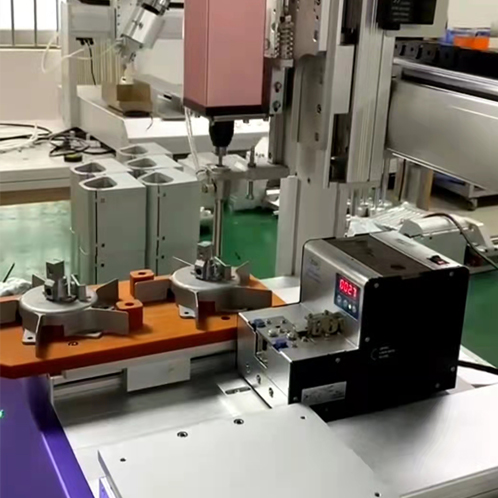

Automatic screw machine: Integrated feeding system and tightening module, realizing automatic sorting, conveying, and locking of screws. ?

??

Process flow and quality control

Material supply and positioning:

The vibrating disc or air blowing feeding system arranges and transports the screws to the locking position, ensuring the correct direction of the screws through optical/mechanical sensors; ?

The suction nozzle or guide tube of the automatic screw machine accurately positions the assembly holes of screws and electrical components. ?

Lock payment execution:

?

Electric screwdriver or servo driven tightening gun completes locking according to preset torque and angle, with built-in sensors for real-time monitoring of tightening status; ?

Abnormal detection (such as missing locks, slipping teeth) triggers alarms and suspends operations to reduce the rate of defective products. ?

Quality verification:

?

The finished product needs to be verified for screw tightness through a torque tester to ensure compliance with the structural strength requirements of household appliances. ?

??

Technical advantages and applicable scenarios

Efficiency improvement: The single piece locking cycle of the fully automatic screw machine can be shortened to a few seconds, suitable for large-scale home appliance production lines; ?

Compatibility extension: Supports multi scenario applications from micro screws (such as circuit board fixation) to large screws (such as shell assembly); ?

Cost optimization: Reduce material waste and manual intervention through functions such as screening irregular screws and automatic material replenishment. ?