|

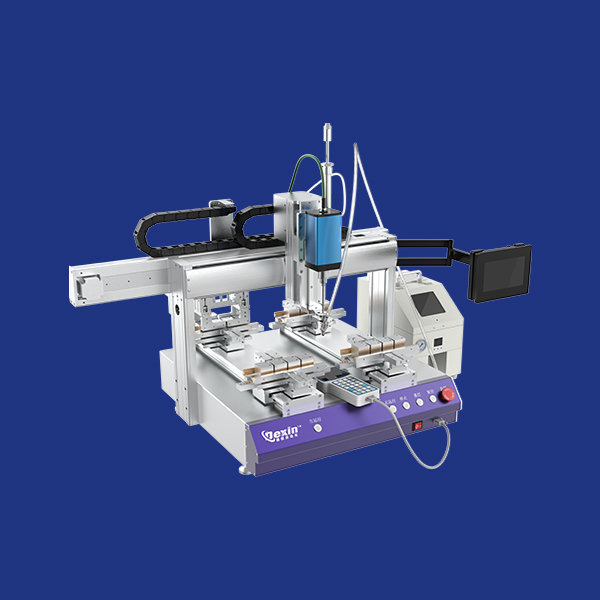

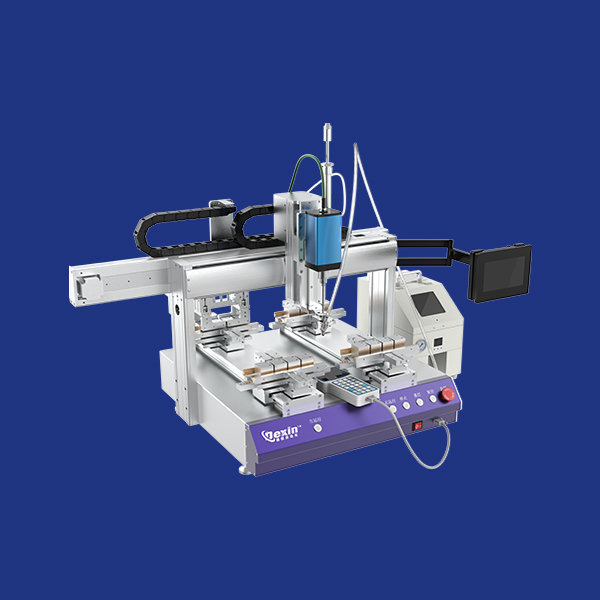

Automatic material screw machine |

|

|

Scope of work: |

X500*2Y300*Z100 |

|

Maximum speed: |

300mm/sec |

|

Repetition accuracy: |

±0.01mm |

|

Transmission mode: |

Brand stepper motor/belt |

|

Locking screw method: |

Servo electric batch air blowing feeding screw nozzle |

|

Power Supply: |

AC220V 50-60HZ 1.5KW |

|

Weight: |

About 60KG |

|

Work environment: |

Humidity 20-90% ℃ Temperature 0-30 ℃ |

|

characteristic:The air blown feeder can load a large number of screws, including long screws, with stable and real-time monitoring of feeding. The servo electric batch has strong stability and real-time monitoring of screw torque; Automatic material retrieval reduces manual labor, facilitates material handling, and allows for real-time monitoring of reliability |

|

|

Characteristics of servo electric batch |

|

1. No mechanical gear and clutch structure, no wear, maintenance free, long service life, low failure rate |

|

2. High precision current sampling and terminal value algorithm drive, fast response, high repeatability, and precise torque |

|

3. Multiple working modes, single-stage, multi-stage, and gear mode, adjustable speed and torque, intelligent locking |

|

4. The driver comes with a 2.4-inch true color touch screen that can be used to debug parameter settings, making it easy to monitor and debug the operation of the electric batch |

|

5. The IO signals of the drive controller include electric batch start stop, electric batch reverse, torque reaching, and electric batch alarm output signals |

|

6. Integrate a 485 communication port based on MODBUS RTU protocol, external controller or touch screen |

|

7. Computer management software, read and save data, display torque curve (optional for docking with factory MES system) |

|

power |

torque |

RPM rotational speed |

Applicable screws |

|

50 watts |

0.3-4kgf.cm(0.03-04N.m) |

10-850 |

M0.6-M2 |

|

100 watts |

1-9kgf.cm(0.1-0.9N.m) |

10-3000 |

M1-M3 |

|

200 watts |

3-18kgf.cm(0.3-1.8N.m) |

10-3000 |

M2-M4 |

|

400 watts |

5-36kgf.cm(0.5-3.6N.m) |

10-3000 |

M2-M5 |

____________________________________________________

Product Download:

Automatic material screw machine.pdf

Automatic material screw machine.pdf