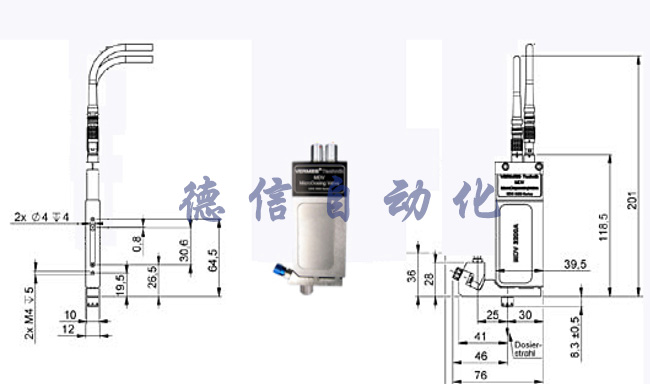

Appearance and size:

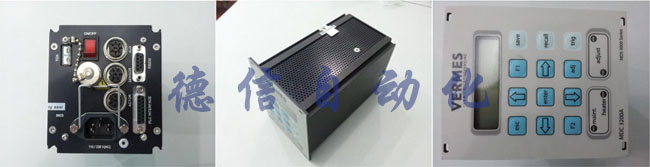

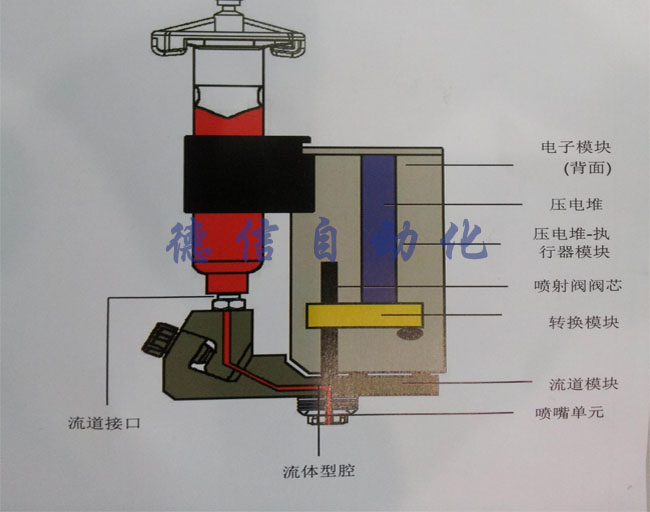

System principle:

Performance advantages of injection valve MDS 3200A:

1. Contactless spraying, high precision, multifunctional

2. Suitable for liquid viscosity up to 2000000mPa

3. High speed: The jet speed is extremely high, with a maximum speed of up to 1000 times per second

4. Multifunctional: Accessories can be freely selected to meet customers' different liquid spraying process needs

5. High precision: It has extremely high repeatability for media of different viscosities, and the automatic calibration function proves that it still has extremely high repeatability after replacing the injection valve. It has extremely high accuracy in spraying positions for small objects, holes, sleeves, and irregular surfaces. Modular design

6. The modular design makes the MDS3200A more versatile, and customers can meet various needs by adjusting the injection valve module separately for different injection processes

Advantages of modular design for injection valves

1. Modular design allows customers to select corresponding components according to different applications, even in high difficulty micro injection applications. Users only need to adjust the injection valve to achieve different injection processes and injection sizes

2. Different nozzle models should be selected for different media or droplet sizes

3. Different shaped top rods can be selected to achieve a perfect spraying experience

4. Customers can choose materials for liquid components according to their needs

Basic parameters

Micro injection valve model: MDS3200A

Applicable media: SMT adhesive (conductive adhesive containing high hardness particles), silicone, bottom filling adhesive and other high viscosity media

Minimum injection volume: 2nl (varies depending on the liquid medium)

Applicable range of drilling depth: 0-200000 mPas

Top pole type: equipped according to customer requirements

Supply pressure: 0-8 bar

Maximum spraying speed: 1000 times per second

Average spraying speed: 250 times/second

Working temperature: 10-50℃

Control mode: After sending a trigger signal, spray according to pre-set parameters,

The number of injections is controlled by an external trigger signal

The size of the sprayed droplets is controlled by an external trigger signal

Size valve: 115 * 39.5 * 12mm

Controller: 101.6 * 295 * 128.4mm

Weight valve: 258q

Controller: 1350g

No current state: Automatic normally closed

Applicable media: Various liquid media, with optional liquid contact components

Heating system (optional): 80 (standard, higher optional)

Feeding device (optional): MDX series

Memory program: 10 items