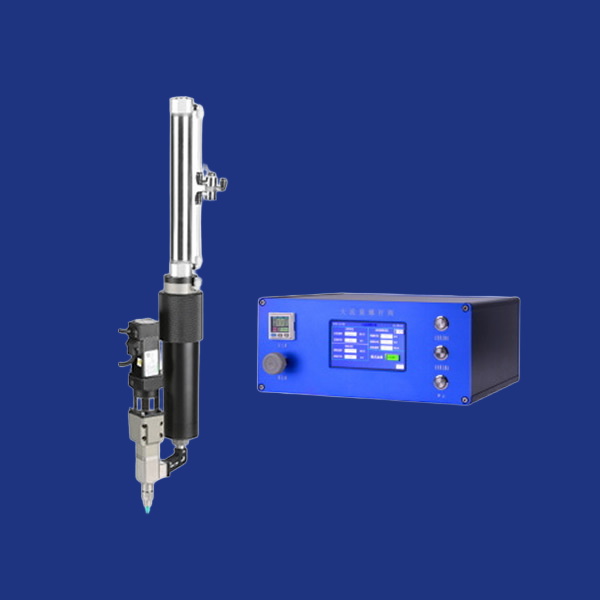

High flow servo precision tungsten steel screw valveProduct Features:

High speed: driven by a 100W servo motor, with a maximum speed of 400 revolutions per minute.

Quick debugging: Adopting the latest module design to simplify tungsten steel screw components.

High efficiency: adopting an efficient screw conveying mode, effectively improving production efficiency

Long lifespan: replaceable screw components made of superhard alloy material, with a longer service life.

High flow rate: using large pitch feeding, multiple pitch options, efficient fluid transportation.

Easy maintenance: Modular tungsten steel screw components that can be quickly disassembled and assembled.

Low cost: The patented design structure requires only a small amount of consumables for maintenance, saving maintenance costs during the production process.

Stability: Adopting spiral fluid conveying method, long-term stable dispensing.

Specification of high flow servo precision tungsten resistant steel rod valve:

Glue dispensing method: Contact dispensing mode

Applicable liquid viscosity: 10000-200000 CPS

Working frequency: Max: 400 revolutions per minute

Applicable needle types: plastic needles, TT angled needles, high-precision needles

Glue supply pressure: Glue pressure: 0.01-0.2Mpa

Valve body mass: 1000g

External dimensions: L60mm*W40mm*H230mm

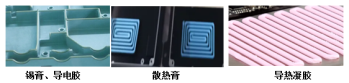

Applicable to liquid type: thermal conductive gel, heat dissipation paste, solder paste, fluid with additives, etc

Controller specifications:

Control mode: electronic analog circuit

Glue dispensing time control: digital circuit/parameterization

Power supply/power: AC220V/50Hz*120W

Controller mass: 2kg

External dimensions: L280mm*W240mm*H120mm