|

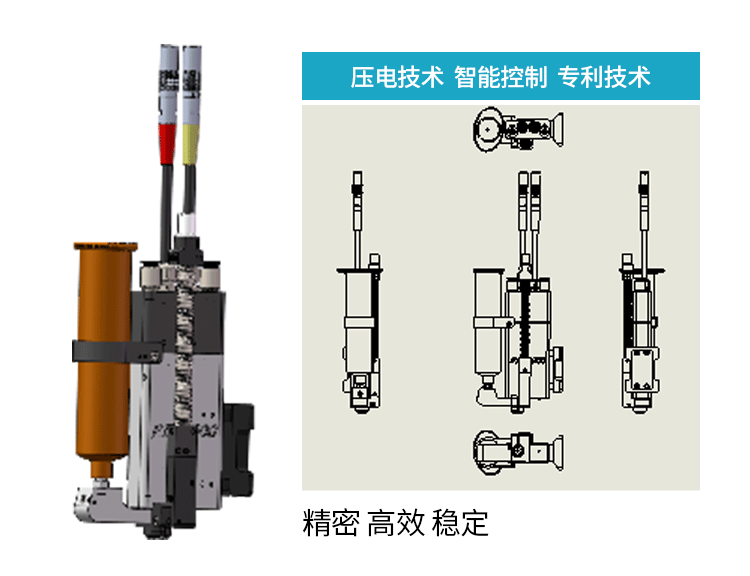

Solder paste spray valvebrief introduction |

|

|

|

1. Latest piezoelectric drive device, faster dispensing speed, maximum frequency of 1000Hz |

|

2. Automatic nozzle adjustment function, achieving visual adjustment (Adj) |

|

3. Unique control method that can achieve variable frequency spraying operation consistent with platform speed |

|

4. Adopting non-contact point soldering method to eliminate Z-axis movement and improve production efficiency |

|

5. A replaceable needle nozzle made of superhard material. Has an extremely long service life |

|

6. Minimum tin content of 2nl, minimum line width of 0.25mm, minimum diameter of 0.2mm |

|

7. The consistency of tin content can reach 90% |

|

8. Unique nozzle constant temperature system ensures that the viscosity of solder paste is not affected by temperature and maintains consistency |

|

9. New nozzle, flow channel structure design, minimal consumables, easy disassembly and maintenance |

|

10. Suitable for high-temperature solder paste, modular switching |

|

DEX9000 Technical Parameters |

|

|

name |

Piezoelectric spray tin valve |

|

model |

DEX9000 |

|

Applicable Medium |

4 # High temperature solder paste with powder or above |

|

Minimum injection quantity |

2nl (Different solder pastes vary) |

|

Applicable range of viscosity |

0-200,000mPas |

|

Top pole type (firing pin) |

Equip according to customer requirements |

|

Supply pressure |

0-0.3Mpa |

|

Maximum jet velocity |

1000 times/second |

|

operation temperature |

Nozzle temperature 25-50 ℃ |

|

Introduction to DEX9000 |

|

1. Equipped with domestically leading nozzle calibration function (CTMU), it maximizes online efficiency and injection accuracy, achieves rapid maintenance of piezoelectric injection valves, and improves production efficiency |

|

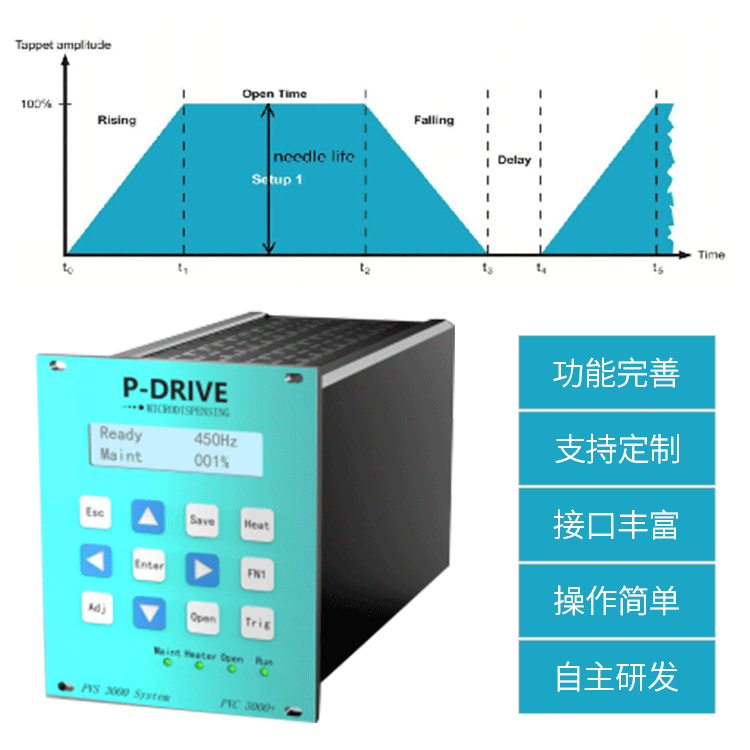

2. More flexible parameter design, adjustable firing pin rise (RI) and fall (FA) time and voltage (NL) range, to achieve higher quality tin application. |

|

3. High precision soldering time setting, can be set to 0.01ms |

|

4. High precision control (trapezoidal wave drive) for piezoelectric valves, real-time diagnosis of system operation status |

|

5. Complete upper computer design, which can achieve remote setting and monitoring through serial port RS232S |

|

6. Can set tin plating mode: dot, line, fixed point; Can be manually OPEN (cleaning), TRIG (triggering), ADJ (calibration) |

|

7. Product size: 198 * 102 * 128mm |

|

8. Maximum current consumption 2A |

|

9. Standard configuration includes 1 nozzle heating 24V PT100 50W |

|

10. The maximum frequency can be set to 1000Hz |

|

11. Input power supply voltage: 110/220V AC |